Metalworking

Custom manufacturing according to the Customer’s documentation.

Experimental, serial and small-series production using modern high-tech equipment made by internationally famous manufacturers.

established in February 2009

At the stage of the initial organization of our business, we’ve been focused on the manufacture of structures and components for the cabin of civil aircraft.

In the process of development and growth of our company, we expand production capacities, implement new and cutting-edge technologies for manufacturing process.

The quality system implemented at our production facilities is based on the requirements of the Aviation Regulations FAR-21.

In order to further develop in the field of ISO 9004-1-94 “QUALITY MANAGEMENT AND QUALITY SYSTEM ELEMENTS”, in 2017 we introduced TechnologiCS automatized enterprise control system.

In January 2021, our company was certified for compliance with the requirements of GOST R ISO 9001-2015 (ISO 9001: 2015)

"Quality management systems. Requirements".

Kvand-ST JSLC

offers manufacturing

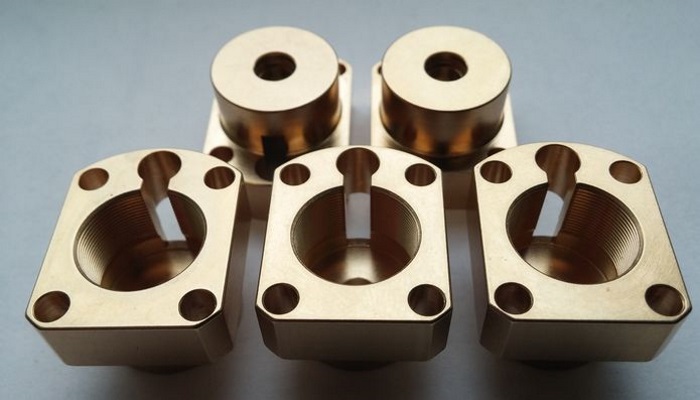

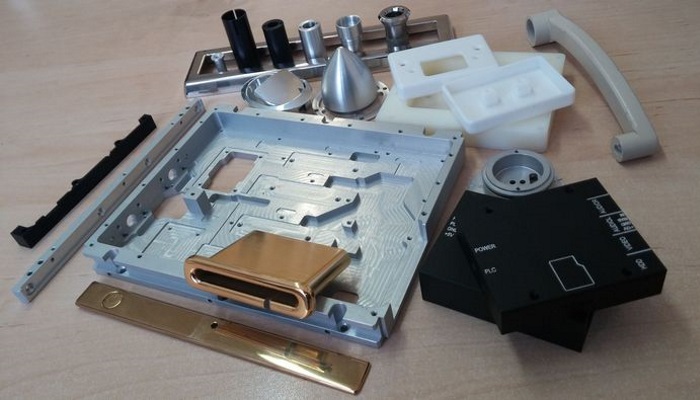

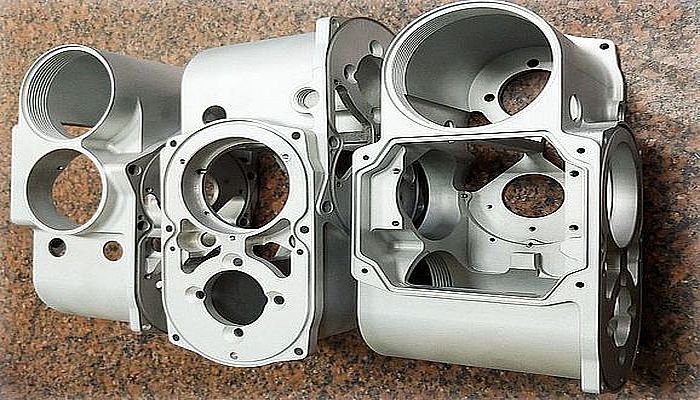

parts, components and integral units according to the Customer’s documentation (according to the provided design documentation and the manufacturing technology developed by us, or provided by design documentation and technological documentation, in strict compliance with all technological requirements of the Customer) from a wide range of materials: structural and stainless steels, alloys of aluminum, brass, copper, bronze, titanium.

We provide trial, serial and small-series production.

Our professional staff and high-performance modern equipment allow us to carry out orders in strict accordance with accepted technical requirements.

Ordered products are made within optimum time frames and at competitive prices.

The production of our company is used in the aerospace and medical industries, instrument making, precision mechanics, etc., in the territory of the Republic of Belarus, as well as abroad.

Services

Turning

Turn-milling

processing diameter ⌀3-⌀20 mm, processing length - 220 mm (per pass), accuracy - 0.02 mm (0.01)

CNC Turning

on a machine with a manipulator (operational autoloading).

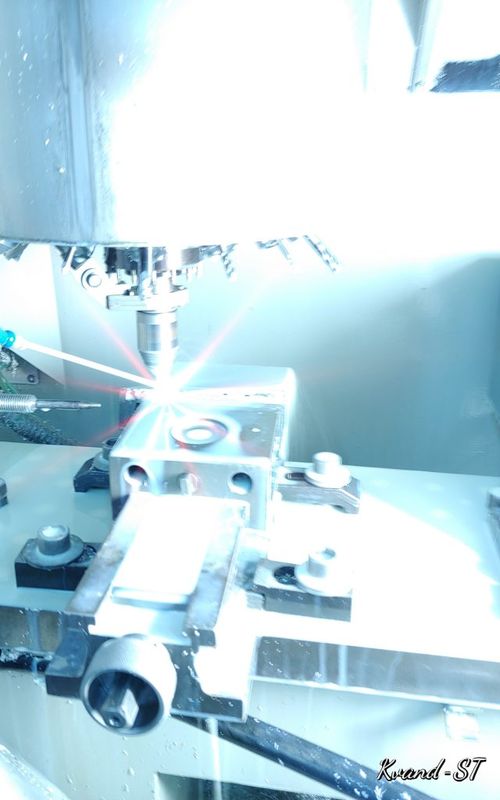

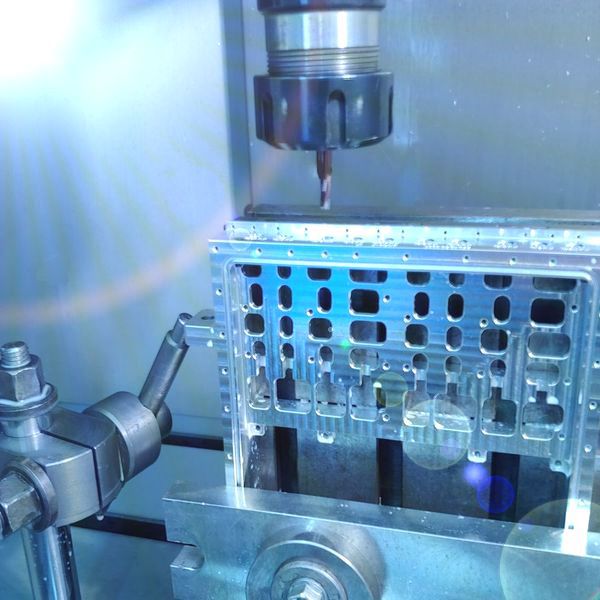

Milling

at CNC machining centers (3-coordinate): with a product processing zone of 1000x600x500 mm, accuracy 0.02 mm (0.01–0.005)*.

Milling three-dimensional volumetric products.

High performance milling

on a 4-axis machining center: X-300, Y-200, Z-250 mm.

High performance drilling and screw-cutting operations

on a 4-axis machine: X-200, Y-150, Z-250 mm.

Milling cutting of colored sheet material

processing area per pass 600x900 mm, accuracy 0.02 mm over a length of 300 mm.

Engraving

edge tools (with CNC).

Welding

argon-arc (aluminum alloys, alloy and stainless steels).

Volumetric heat treatment

Locksmithing

material processing, product refinement and aggregate assembling of units.

Sheet bending

(length 2000x3 mm)

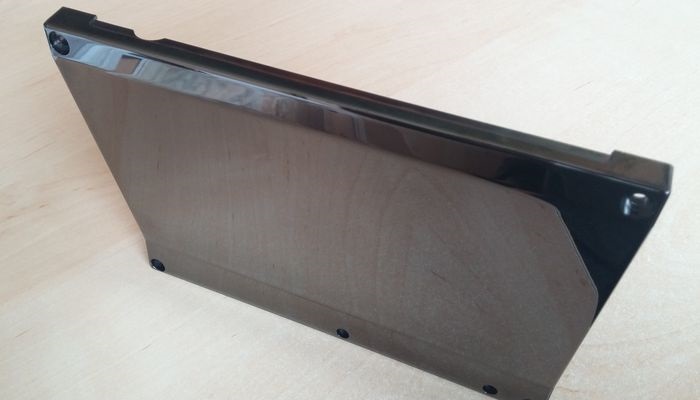

Finishing

(polishing, tumbling and vibro-abrasive treatment, sandblasting, grinding/ polishing, preparation for coatings)

During production process, in order to provide the Customer with the full range of services, laser cutting, galvanic, ion-plasma coatings, electrochemical polishing, heat treatment of materials, paint-and-varnish and polymer coatings are subcontracted (cooperation).

Equipment

- HAAS CNC machining centers, CINCINATTI, CHIRON, ALZMETALL, TOS (3-axis).

- FANUC CNC Lathes.

- Swiss type sliding head lathe with CNC.

- NAKAMURA TOME TC-12 (Japan) CNC machine with a manipulator (operational autoloading).

- CHIRON (Germany) 4-axis machining center.

- BROTHER (Japan) 4-axis machine.

- MEYER (Switzerland) bending and pressing equipment.

- AGIE (Switzerland) erosion copy-stitching machine.

- Welding equipment with a shielding gas environment.

- Tumbling and sandblasting equipment.

- NABERTHERM CNC muffle furnace.

- Control-and-measuring equipment: ZEISS ECLIPSE (CNC), HEXAGON, TESA, MAHR.

Portfolio

Contact Us

Kvand-ST Joint Stock Limited Company

Office 11, 72, Asanalieva str., Minsk, 220024, Republic of Belarus

Tel./fax (+375 17) 270-11-88, 270-11-89, 270-11-90

Tel. (+375 29) 622 57 55

e-mail: kvand_st@tut.by, kvand.st@gmail.com

INTERMEDIARY BANK COMMERZBANK AG FRANKFURT AM MAIN, GERMANY

SWIFT CODE: COBADEFF

BENEFICIARY'S BANK ACC. № 400886629500

«BANK DABRABYT» JSC, MINSK BY SWIFT CODE: MMBNBY22

BENEFICIARY acc. BY66MMBN30120362800309780000